Contact · Newsletter · DEUTSCH

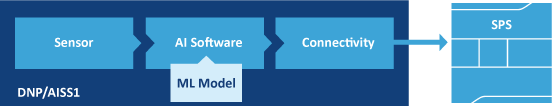

The new AISS (Artificial Intelligence Smart Sensor) product family uses a modular concept to enable the rapid and individual development of intelligent sensor systems that are tailored to the task at hand.

This allows virtually any controller to be retrofitted with artificial intelligence (AI) and machine learning (ML).

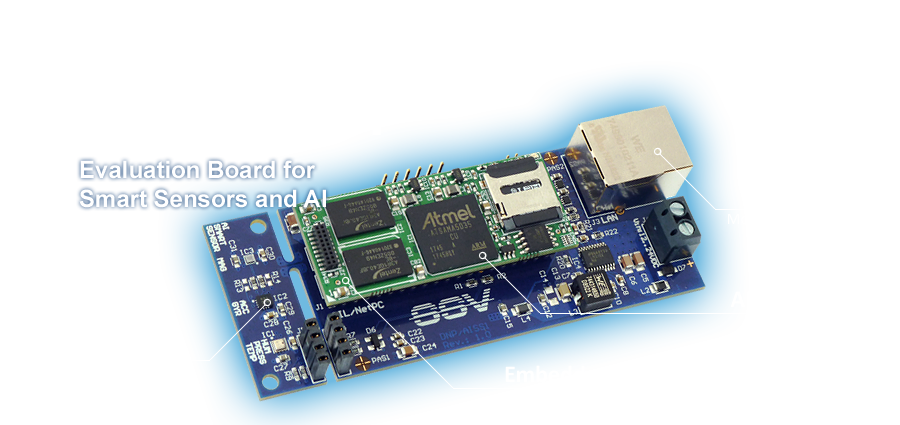

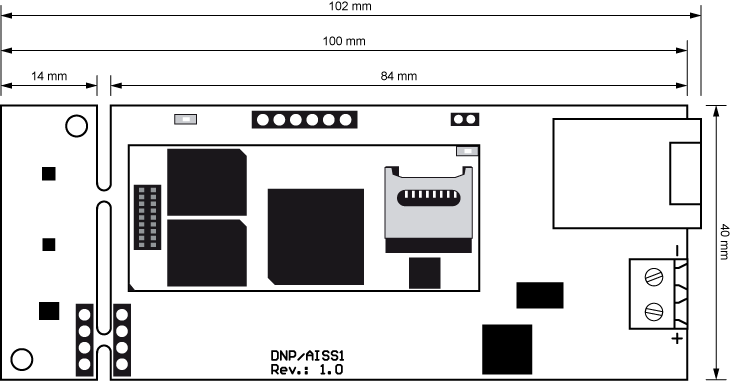

The first representative of the new AISS family is the evaluation board DNP/AISS1. In addition to various sensors, it offers a compact embedded system (DNP/9535) including AI and connectivity software.

In addition, different housing variants from IP20 to IP67 are possible. Another highlight is a first steps webinar included in the scope of delivery.

The DNP/AISS1 is equipped with the following three sensor elements from Bosch:

AI algorithms are used to extract the desired information from the raw sensor data and make it available to other systems via Ethernet connectivity.

The DNP/AISS1 is equipped with an Ethernet interface. The software supports the following protocols:

In addition, VPN remote access functions as well as the Node-RED data flow software are also part of the connectivity.

The following Python Data Science functions are the main components of the AISS technology stacks:

This allows, for example, model development and evaluation of predictive maintenance applications and anomaly detection.

The entire system is controlled by the DIL/NetPC DNP/9535. This compact embedded system contains the AISS technology stack with the various AI software modules.

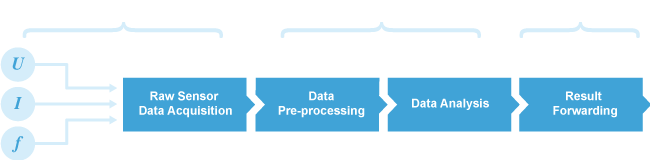

The DNP/9535 is based on a powerful embedded Linux platform to run directly on site and in real time (edge/fog computing) through the following four-step processing chain:

In addition, the DNP/9535 has the Node-RED data flow software installed, which can also be used to access the output values of the AI algorithms for further tasks.

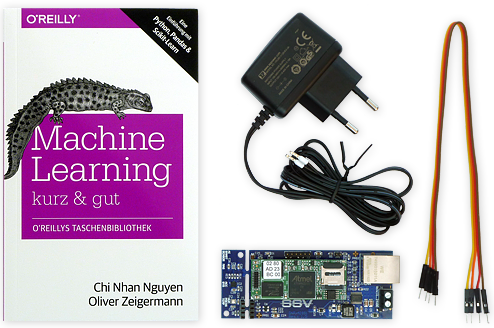

To assist with the launching and evaluating of the DNP/AISS1, the scope of delivery also includes a webinar with the following content:

1. Basic principles and terminology of machine learning.

2. A complete machine learning process, including sensor data acquisition, data preparation, modeling and model evaluation.

3. Evaluation and adaptation of machine learning models.

4. Connecting the output of an AISS machine learning algorithm to a PLC or cloud.

This provides the user not only with the hardware and software, but also with the knowledge needed to be able to independently develop machine learning applications and thus, retrofit any PLC application with artificial intelligence.

With the aid of the AISS modular system, an individual AISS solution can be put together that is precisely matched to the intended task. The evaluation board DNP/AISS1 serves as a basis and is modified as desired, which significantly accelerates the development of an own system.

The interaction of the individual components of the AISS modular system creates an application-specific sensor with a four-stage processing chain.

A wide range of sensor elements are available here for almost any application, such as inertial sensors, compass or sensors for volatile gases.

In this toolbox, intelligent algorithms for data analysis that are based on the Python programming language can be found, as they are also included in the AISS technology stack.

This toolbox offers various components for communication and security, e.g. for wireless data transmission.

The components for power supply (e.g. for battery operation), power management and the final product housing (IP20 to IP67) are included here.

A 3-axis robot with gripper arm is controlled by a PLC to transport components from location A to location B.

Usually, the PLC is not able to detect a mechanically induced anomaly on the robot gripper arm in time, and would continue until the anomaly causes damage and it "cracks".

It won't be of any help either that the required sensor elements – such as a 3D acceleration sensor – could be retrofitted relatively easily.

Now, if you connect a DNP/AISS1 between the sensors and the PLC, the situation changes completely: the DNP/AISS1 cyclically links the 3D sensor data and classifies the state of the robot using a pre-trained machine learning algorithm.

This produces a discrete output value, which is passed on to the PLC via Profinet. Based on this value (which is generated with the help of intelligent algorithms), the PLC can now detect an anomaly and indicate a malfunction.

Conclusion: Every control application can be retrofitted with intelligent functions through artificial intelligence, such as those that are available for machine learning (an AI or machine learning retrofit, so to speak).

This makes a PLC more adaptable and allows it to react in borderline situations (e.g. the occurrence of an anomaly) that were not foreseen or pre-programmed when the controller was developed. This allows service work to be planned more precisely and the availability of a machine or plant to be improved.

For an AISS to even recognize an anomaly on the robot gripper arm as such, as in the example used above, an AI algorithm must first be selected and trained.

Selection and training takes place in the so-called Exploration & Modelling Mode (EMM for short) of the AISS. In this operating state, a model for the AI algorithm is generated via machine learning (ML).

Before that, however, some important questions need to be clarified:

Once these questions are answered, a suitable ML model can be generated and validated using supervised machine learning on an external computer as the development system.

For this, the sensors on the gripper arm transmit their raw data in the desired frequency as so-called n-dimensional feature vectors to the connectivity component of the AISS, which forwards the data via Ethernet LAN to the development system (e.g. R, Jupyter, MATLAB...).

This way, an ML model of the respective robot operation is created on the development system based on the data of the AISS sensors. The learned model is then validated in several test runs with the aid of further sensor data and, if necessary, trained again until a satisfactory result is obtained with regard to the classification or prediction accuracy.

This way, an ML model of the respective robot operation is created on the development system based on the data of the AISS sensors. The learned model is then validated in several test runs with the aid of further sensor data and, if necessary, trained again until a satisfactory result is obtained with regard to the classification or prediction accuracy.

In the Exploration & Modelling Mode, a model for a specific AI algorithm is generated and validated on a development system via supervised machine learning. For this, the DNP/AISS1 provides raw sensor data as n-dimensional feature vectors.

The ML model generated and tested in the training mode is loaded into the AISS, which can then begin its actual work in the so-called Inference Engine Mode (IEM for short). In this mode, a periodic data analysis in conjunction with a continuous result forwarding to external systems takes place.

During the normal operation mode of the robot, the AI algorithm of the AISS periodically compares the current data patterns in real time with those of the model and, in the event of deviations, causes the PLC to send a warning message or switch of the robot, for example.

The sensors of the robot cyclically transmit the measured feature vectors as objects to the AI algorithm, which classifies

these objects in a so-called feature space (the exact procedure depends on the respective algorithm).

The feature space is a multidimensional mathematical space. The position of a particular object in this space is determined in each case by the individual measured values of a vector. Each sensor measurement value of the feature vector corresponds to one dimension.

The AI algorithm evaluates the positions of the feature vectors based on the learned data of the ML model and provides an output value (e.g., the classification of the position of a vector within the learned ranges) to the connectivity component.

The AI software compares in real time the current measurements of the sensors with those of the ML model generated in the EMM (see above) and provides an output value to the PLC via the connectivity.

SSV SOFTWARE SYSTEMS

Dünenweg 5

30419 Hannover

Phone: +49(0)511 · 40 000-0

Fax: +49(0)511 · 40 000-40

© 2026 SSV SOFTWARE SYSTEMS GmbH // All rights reserved.

ISO 9001:2015