Contact · Newsletter · DEUTSCH

Sensor data for Smart Factory digitalization tasks require significantly higher-quality informational content than, for example, in classic flow control applications.

Through a selection of sensor elements suitable for the task, sensor fusions for linking different measured values and AI algorithms, the raw sensor data in the SSV sensor solutions become valuable information that can be used for various tasks

in process optimization, machine and plant maintenance as well as intralogistics.

The SFS modular system allows the rapid development of smart (retrofit) sensors with task-specific data output. In addition to the sensor technology and data processing, the housing, the power supply and the communication interface are also individually adapted to the task.

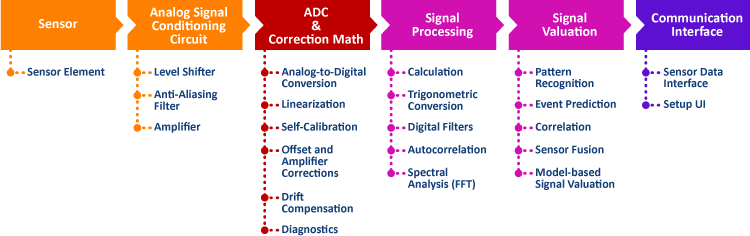

The basic structure of a Smart Factory Sensor can generally be divided into six functional units.

The first two functional units, the sensor and the analog signal conditioning circuit shown in figure 1, are directly connected to an embedded system which provides all the other functional units, including the communication interface, via suitably adapted hardware and software.

These six functional units are divided into four blocks:

Figure 1: Functional units of a Smart Factory Sensor.

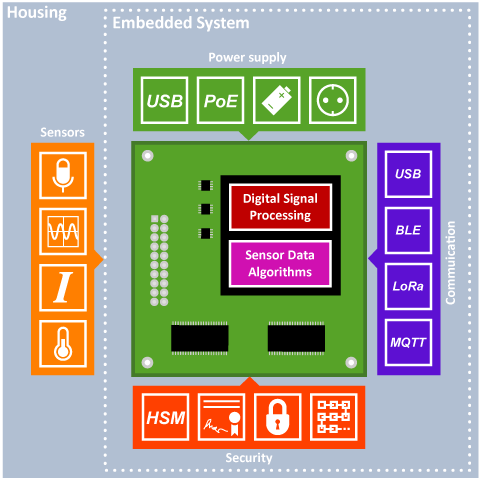

The specific internal design of a Smart Factory Sensor is primarily determined by the measured values required for the planned area of application, the respective connection to the embedded system and the technical requirements for the communication interface for data transfer to other systems and platforms (e.g. an MES).

A Smart Factory Sensor therefore consists of different combinations of sensor elements, measurement methods, communication interfaces, voltage supply systems and housing designs, depending on the area of application.

Figure 2: Building blocks of the Smart Factory Sensor

Depending on the task, the required measured values or sensors are selected.

The communication interface of an SFS has to primarily fulfill the following tasks:

The embedded system is formed by a microcomputer with all necessary software components.

Various single-chip microcontrollers or small embedded Linux circuits are used here.

The power supply is designed depending on the specific requirements (e.g. 24 VDC, battery, Power over Ethernet).

The SFS modular system contains various families of housings from which a suitable option is selected, depending on the requirements (space requirements, protection class, etc.).

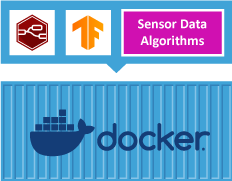

For each Smart Factory Sensor, a support docker with various functions tailored to the respective sensor is supplied as an accessory.

In addition to Node-RED functions, these include a TensorFlow Lite inference interpreter for real-time analysis of sensor data using previously trained neural networks to generate the desired information for forwarding to higher-level systems, such as an MES.

The SFS/BE1 Bluetooth evaluation board can be equipped with various sensor elements, e.g. the BME680 gas sensor or a CCS811 air quality sensor. The respective measured values are continuously transmitted to the sensor support docker together with a digital signature.

In Docker, the sensor data can be preprocessed and analyzed depending on the application. The respective result is transmitted to the controller using a suitable protocol.

The SFS/BE1 uses the Bluetooth protocol extension Secure Sensor Beacon (SSV/SSB), which was newly developed by us.

A detailed technical description of SSV/SSB can be found here on GitHub.

You are planning to integrate wireless sensor technology into your building or plant control system and want to evaluate different sensor scenarios to create an extended data picture at the control input to improve overall efficiency.

To do this, you need highly secure wireless sensors that are very easy to install and provide your control system with the appropriate data.

Not all machines offer a suitable data interface that can be used to connect to a Docker container. In some cases, a suitable interface exists, but the data required for a specific task is not available.

In this case, the suitable data can be generated using an external retrofit sensor system. In the Docker container, the raw data from the individual controllers and sensors is combined for further processing.

We are a software house with numerous customers who operate larger machine parks as manufacturing companies. We receive requests again and again for various machine data acquisition and data analysis tasks.

These often involve the creation of key figures, such as overall equipment effectiveness (OEE), but also predictive maintenance and maintenance in general.

We want to provide these customers with Docker-based applications for edge gateways that can be flexibly connected to as many machines as possible.

For a Smart Factory Sensor of the SFS family, a sensor element suitable for the respective task is used. In this example, an 8x8 IR (infrared) sensor array is used that provides a total of 64 temperature readings for a given area as digital output data (periodic real-time data).

The IR sensor data is evaluated using a machine learning algorithm (ML Sensor Data Algorithm). For this purpose, an ML model is created in a separate workflow (the ML training phase) and stored in a file.

See also our example "TinyML IR sensor" on GitHub.

In AI-based SFS applications, the open source library TensorFlow is usually used. The ML training phase is done in the cloud. The resulting model file is converted to TFLITE (TensorFlow Lite) or TinyML format and used directly in the OT environment.

We build packaging machines to pack pallets in film. We want to implement condition monitoring for the slip rings in our turntable wrappers. This should reduce the downtime of our customers' automatic turntable wrappers.

For this permanent condition monitoring, a thermal image of the slip ring body is to be continuously generated using an IR thermography sensor and evaluated by a machine learning model.

An AI algorithm checks the IR sensor data in real-time to distinguish between the three states of inactive, normal activity and abnormal activity as reliably as possible and reports them to the machine PLC.

SSV SOFTWARE SYSTEMS

Dünenweg 5

30419 Hannover

Phone: +49(0)511 · 40 000-0

Fax: +49(0)511 · 40 000-40

© 2026 SSV SOFTWARE SYSTEMS GmbH // All rights reserved.

ISO 9001:2015